PowerPoint of Pacamor’s Large Accomplishments in the

Aerospace and Defense industry.

View here: PKBpwr

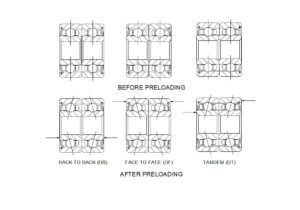

Axially preloading of bearings provides the following benefits:

Axially preloading of bearings provides the following benefits:

COMMON TECHNIQUES

SPRING method is the simplest method. This method is less sensitive to thermal expansions and contractions. It can also accommodate some misalignment in the system.

WASHER/SPACER method is a more tedious process requiring precise measurements of the endplay and matching it with precision washer/spacers. This method is not as forgiving when subjected to thermal expansions and contractions or misalignment.

DUPLEX method is a process of removing material from a pair of bearing faces to adjust raceway offsets. Clamping the bearing faces together creates the internal preload. Duplex sets assist in satisfying the requirements of increased radial and axial stiffness, and also provide deflection control.

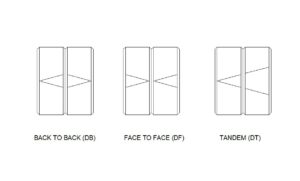

There are (3) methodologies:

PRELOADED PAIR MARKING

The following illustrates PKB’s standard marking scheme for each of the Duplex methodologies.

The “V” in the Tandem set point in the direction of the axial force applied to outer ring.

If you have any questions or inquiries regarding duplex sets, contact us anytime. sales@pacamor.com

Bearing handling is as important as bearing design and cleanliness.

Improper handling can contaminate or damage the bearing assembly.

Proper handling and installation helps to maximize bearing performance and bearing life.

Some Tips:

Contact us with any miniature ball bearing requirements you may have.

PKB’s Clean-Room Bearing Maintenance and Re-lubrication Center meets Class-6, with Class-5 Clean Benches, per ISO 14644-1.

PKB manufactures bearings up to 1.125″ O.D.

Pacamor Kubar Bearings is pleased to offer clean-room services.

Have your ball bearings been in a stock room for 3 years or longer?

Is the lube discolored or the packaging damaged?

Did your stockroom temperature and humidity ever fluctuate?

PKB’s quality certified factory and clean-room are the right place to refurbish your ball bearing inventory.

Who better, than the ball bearing manufacturer, to re-lubricate your aging bearing inventory?

Clean-Room Services:

Lube Weight Documentation

Why Maintain Proper Bearing Lubrication?

Class 6 Clean Room with Class 5 Clean Benches, meeting ISO 14644-1

Proper lubricant can reduce friction, prevent bearing wear, protect bearing surfaces from corrosion, and carry away excess heat during bearing operation.

Bearings operate on a very thin film of lubricant which must be maintained, or replaced, to ensure that maximum bearing life is achieved.

Proper selection, application, and maintenance are vital in maximizing bearing life.

Maintaining your bearings with proper lubrication will reduce friction and wear.

Can PKB Re-lube Bearings That Were Manufactured By Other Companies?

Yes. PKB regularly performs re-lubrication services on bearings that were originally manufactured by other bearing companies.

When Should Bearings be Re-lubed?

PKB recommends that bearings should be re-lubed within three (3) years of the original manufacturer’s lube date, or if any of the following conditions occur:

Can’t I Just Wash Out the Lubrication and Install New Lube?

Many 440C Stainless Steel Bearings that are used in Aerospace, Medical, and other applications, can be cleaned and re-lubricated, in proper clean-room conditions, and by trained personnel. Improper handling can result in cross contamination, problems with wettability on balls & bearing races, or ball & raceway damage. Other components affected or broken, are the retainers, seals, shields, balls, or wires. PKB provides bearing wash and re-lubrication services, for many Aerospace OEM’s and authorized re-sellers, in our factory clean-room.

| Bearing Lubrication – Most Requested Oils | |||||

| Lubricant | Type | Viscosity (Centistokes) @ 100 F |

Viscosity (Centistokes) @ 210 F |

Operating Range (F) | Mil-Spec |

|

WINSOR L245X |

DIESTER | 31 | 5.3 | -65 to +300 | MIL-L-6085A |

| ANDEROL 401D | DIESTER | 11.5 | 3.2 | -65 TO +300 | – |

| DC 510 | SILICONE | 38 | 14 | -65 to +500 | MIL-L-27694 |

| KRYTOX143AC | FLUOROCARBON | 260 | 26 | -30 TO +550 | – |

| Bearing Lubrication – Most Requested Greases | |||||

| Lubricant | Base Oil | Thickener | Color | Operating Range (F) | Mil-Spec |

| ROYCO 27 | DIESTER | LITHIUM | BROWNISH | -100 TO +300 | MIL-G-23827 |

| BEACON 325 | DIESTER | LITHIUM | LIGHT TAN | -65 TO +250 | MIL-G-3278 |

| BRAYCOTE 601 | PERFLUORINATED POLYETHER | TETRAFLUORO-ETHYLENETELOPMER | BEIGE | -100 TO +500 | – |

| MOBIL 28 | HYDROCARBON | CLAY | DARK RED | -65 TO +350 | MIL-G-81322 |

| SRI-2 | MINERAL | POLYUREA | BLUE / GREEN | -20 to +350 | MIL-G-3545G |

| KRYTOX 240AC | FLOURINATED GREASE | VIDAX | WHITE | -30 TO +550 | MIL-G-27617 |

| AEROSHELL 22 | SYNTHETIC HYDROCARBON | MICROGEL | AMBER | -85 TO +400 | MIL-G-81322 |

Please Contact PKB for a quote to rework your in-house bearings, with new lubricant, or to make a lubricant change.

sales@pacamor.com

More about Bearing Lubrication from PKB:

The most popular bearing lubricants are listed on our Lubrication Page. Many more oil, grease and dry-film lubricant options are available, upon request.

More How-To Guides:

We are excited to discuss with you our miniature and instrument bearing capabilities.

We are excited to discuss with you our miniature and instrument bearing capabilities.

PKB manufactures ball bearings for some of the world’s most respected small motor brands.

We also offer:

– SHORT LEAD-TIMES

Shorten your ball bearing lead times with our domestically produced bearings, manufactured and assembled in Troy, NY.

– COMPETITIVE PRICES

Best prices in the domestic bearing industry!

Reduce your domestic ball bearings costs with our Veteran-American Owned & Operated Small Business.

– RELIABLE QUALITY

Expedite time to market for your new and updated products.

– PROTOTYPE SPECIALISTS

Your engineers will love our speedy delivery of engineering prototypes and evaluation samples.

Here is a testimony, about PKB bearings, for small motor applications, from Kearfott Guidance & Navigation

Here is a testimony from another happy customer. This one is for PKB cryogenic bearings for Flowmeter applications, from the President of Hoffer Flow Controls

Our wide range of miniature and instrument bearings are used in an array of small motors, actuators, encoders, often found in aerospace, space, military, medical and surgical applications.

Our wide range of miniature and instrument bearings are used in an array of small motors, actuators, encoders, often found in aerospace, space, military, medical and surgical applications.

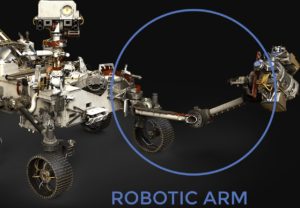

We have proudly supplied products for the NASA Docking Station, NASA James Webb Space Telescope, MARS 2020 Rover, Sikorsky Helicopters, Cryogenic Flowmeter Applications, FAA TSO-C149 Aircraft Bearing applications, many military and Department of Defense (DoD) applications, as well as other space, aerospace, medical, and customized applications.

Pacamor Kubar Bearings – sales@pacamor.com

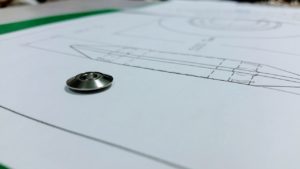

The bearing industry was once again rocked by news of widespread counterfeiting. Bearing manufacturer SKF reported the identification and destruction of 15 tons of counterfeit bearings, totaling approximately 17,000 bearings.

As quoted in the Automotive World article: End customers that install counterfeit components will suffer the most. A recent case proved once again that significant damage can be caused by the failure of a rolling bearing. An anonymous customer says: “We spent EUR 100,000 on large size bearings, purchased from an un-authorized supplier. We needed the bearings urgently and the supplier matched our required lead time. Their failure was a fact after only a few months, while the expected service life was several years. We faced costly downtime and broken promises to our customers. All this could have been avoided, by more awareness and caution in our sourcing. We will not allow this to happen again.”

Ed Osta, President of Pacamor Kubar Bearings (PKB), warns against the ease of getting duped by counterfeit bearings. “Tight profit margins combined with the influx of cheap import products make bearings an extremely competitive business”, says Osta. “Counterfeit bearings may resemble the branded product, at first glance. However, they may have been manufactured using substandard materials, not to standard ABEC tolerances and assembled in less than optimal conditions. These discrepant bearings can often fail, sometimes destroying an entire system along with the reputation of the system’s manufacturer. When parts are destined for critical applications, even the smallest nonconformity can cause catastrophic failures.”

Pacamor Kubar Bearings (PKB) is deeply concerned by these risks to parties who put their trust in counterfeit and unapproved parts. PKB takes pride in product quality, workmanship, knowledge and skill as experts in the production of high quality aerospace bearings. The entire PKB factory is AS9100 Rev D & ISO 9001:2015 certified and all of the DFARS approved products are FAA TSO-C149 Aircraft Bearings certified. If the package isn’t shipped directly from PKB, or from one of a very few PKB approved re-sellers, be sure that the product you are buying is original PKB manufactured product.

Contact PKB directly or through a very short list of approved distributors. sales@pacamor.com

Authentic PKB Aerospace Bearing at the Pacamor Kubar Bearings factory, in Troy, NY.

Why work with us?

![]()

– SHORT LEAD TIMES

Shorten your ball bearing lead times with our domestically produced bearings, manufactured and assembled in Troy, NY.

– COMPETITIVE PRICES

Best prices in the domestic bearing industry!

Reduce your domestic ball bearings costs with our Veteran-American Owned & Operated Small Business.

– RELIABLE QUALITY

Expedite time-to-market for your new and updated products.

– PROTOTYPE SPECIALISTS

Your engineers will love our swift delivery of bearing prototypes and evaluation samples.

S/N Precision Enterprises Inc., dba Pacamor Kubar Bearings – Cage Code 14927

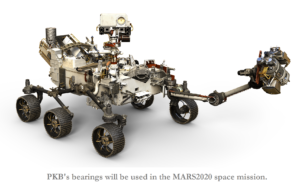

Pacamor Kubar Bearings (PKB), a Troy, NY manufacturer of ball bearings for aerospace and defense systems, was recently awarded a contract by Sierra Nevada Corporation (SNC) to supply critical hardware for the Mars 2020 mission. Scheduled to launch in 2020, the robotic science rover will investigate key questions about the habitability of Mars and assess natural resources and hazards in preparation for future human expeditions to the red planet. Under the new contract, PKB will manufacture ball bearings for several motors in the robotic arm actuator and sample caching system. The instruments will enable scientists to identify and select a collection of rock and soil samples that will be analyzed and stored for potential return to Earth.

Pacamor Kubar Bearings (PKB), a Troy, NY manufacturer of ball bearings for aerospace and defense systems, was recently awarded a contract by Sierra Nevada Corporation (SNC) to supply critical hardware for the Mars 2020 mission. Scheduled to launch in 2020, the robotic science rover will investigate key questions about the habitability of Mars and assess natural resources and hazards in preparation for future human expeditions to the red planet. Under the new contract, PKB will manufacture ball bearings for several motors in the robotic arm actuator and sample caching system. The instruments will enable scientists to identify and select a collection of rock and soil samples that will be analyzed and stored for potential return to Earth.

“PKB has been supporting NASA’s Jet Propulsion Laboratory (JPL) programs and missions for over 10 years,” said Ed Osta, president of Pacamor Kubar Bearings. “We are grateful for NASA and SNC’s continued confidence in our ability to produce reliable aerospace bearings for these vital missions. PKB is committed to the success of this mission and proud to partake in this project. We look forward to continuing our longstanding relationships with JPL and SNC.”

PKB understands the unique challenges presented by aerospace and guidance applications. Temperature extremes and the vacuum of space create demanding requirements for the lubricant type and its ability to withstand the environment. To meet this demand, PKB is providing precise and reliable products in support of successful missions.

“SNC appreciates the PKB’s commitment to deliver the promised product within the assured timeline,” said Jason Priebe, vice president of productions/operations for SNC’s Space Systems business area. “Reliable suppliers are crucial to developing a final product that you’re proud to stand behind.”

ABOUT PACAMOR KUBAR BEARINGS

PKB is ISO9001:2015 and AS9100D certified, which includes the additional QS requirements specific to the aerospace industry. The company attained certification from the FAA to manufacture bearings per the requirements of TSO-C149, thereby enabling it to provide bearings as replacement parts to FAA certified repair stations. PKB is JCP-Certified, which is a joint certification program with United States and Canada.

Pacamor Kubar Bearings manufactures high performance DFARS-compliant miniature and instrument ball bearings for the aerospace, defense, medical, industrial and commercial industries. Customers include major aerospace manufacturers and key re-sellers as well as various national laboratories and prestigious government organizations such as NASA. PKB provides these industries with precision ball bearings, including those with unique designs and materials used at sub-cryogenic temperatures.

For more information on PKB, please follow us on our facebook page, and on our instagram feed.

Pacamor Kubar Bearings offers the right bearing at the right price, for all your miniature, precision, and instrument applications.

“Life” is the number of hours that a percentage of similar bearings have survived under an essentially identical set of operating conditions and loads. Life can be affected by a number of factors including loads, speed, lubrication, fit, maintenance, temperature, contamination, and others.

Bearing life is defined as the length of time (number of revolutions) until a specific failure occurs. Predicting the life of a ball bearing is a statistical calculation of the fatigue properties of the various bearing components. Fatigue Life (L10 or Rating Life) of bearings is the number of hours or revolutions reached by 90% of a group of bearings subjected to the same loads before the onset of fatigue. Conversely, 10% of the same group of bearings can be expected to show evidence of fatigue before the L10 Life is reached.

Many variables can impact bearing life. Various factors such as handling and contamination damage can dramatically reduce bearing life. Bearings should be properly stored, mounted, dismounted, and inspected. Optimized performance and life is also contingent on appropriate lubrication and sufficient protection from foreign matter. Bearings should be stored in a cool, clean, low humidity environment free of dust, shocks and vibrations. Proper fitting, using specialized tools and techniques, will also help maximize bearing life.

For further assistance with bearing selection and design, please feel free to contact our engineering team. Catalog bearings, of all sizes produced by PKB, can be configured as Angular Contact, Radial, or Full-Complement types. PKB also manufactures a wide range of Thin-Section and Metric bearings.

For further assistance with bearing selection and design, please feel free to contact our engineering team. Catalog bearings, of all sizes produced by PKB, can be configured as Angular Contact, Radial, or Full-Complement types. PKB also manufactures a wide range of Thin-Section and Metric bearings.

See our Bearing Installation Guide & Bearing Handling Practices pages for more information about proper installation of a PKB bearing into your device. Be sure to visit our Shaft and Housing Fits page for a detailed chart and more information about this topic.

For further assistance with bearing selection and design, please e-mail sales@pacamor.com